Call: 08045815461

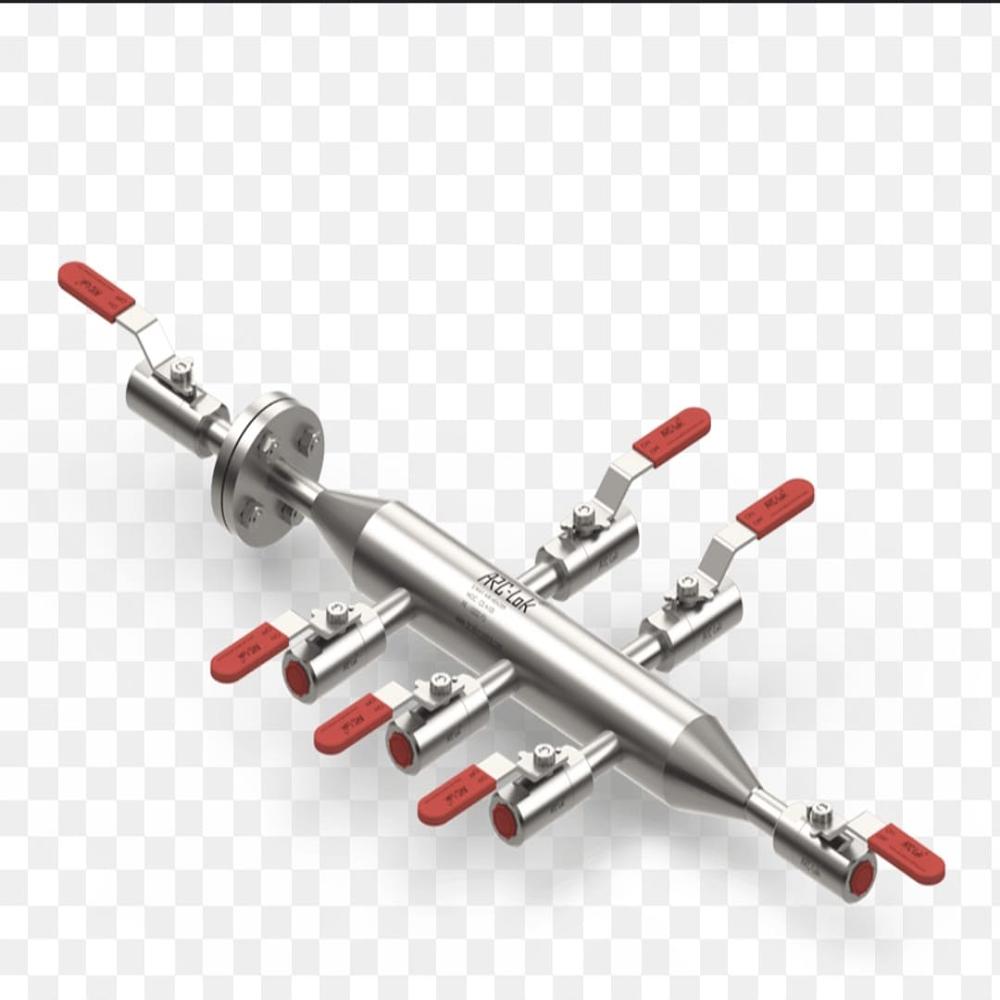

Air Headers

Price 11000.0 INR/ Piece

Air Headers Specification

- Surface Treatment

- Polished

- Features

- Cost effective, Proper execution

- Type

- Air Headers

- Material

- Mild Steel

- Product Type

- Air Headers

- Function

- Low Power Consumption

- Color

- Black, Silver, Blue

- Application

- Industrial Use

Air Headers Trade Information

- Minimum Order Quantity

- 15 Number

- Payment Terms

- Letter of Credit (L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, Central America, Australia

- Main Domestic Market

- All India

About Air Headers

We can provide different kind of air headers with the world class quality at very reasonable price. Below are the some of the standard headers which we are supplying regularly to chemical plants.

1. 8 points air headers

2. 10 points air headers

3. 12 points air headers

4. 20 points air headers.

Air headers are provided fully customized without any extra cost of designing and material used are CS | SS304 | SS316.

We prefer SS material as it has long life due to anticorrosive material.

Optimized for Industrial Demands

Our mild steel Air Headers are tailored to suit diverse industrial applications, prioritizing both performance and longevity. The polished finish ensures corrosion resistance and an appealing look, while the low power consumption design helps businesses optimize operating costs.

Versatile Sourcing and Support in India

As a trusted partner in India, we offer comprehensive solutions-spanning distribution, manufacturing, exporting, and attentive after-sales service. Whether sourcing for a new project or expanding operational capabilities, our expertise and quality assurance stand ready to support your enterprise.

FAQ's of Air Headers:

Q: How are air headers used in industrial environments?

A: Air headers are installed to distribute compressed air from a central supply line to multiple branch lines, supporting various pneumatic tools and instruments typically found in industrial settings.Q: What is the primary benefit of choosing mild steel polished air headers?

A: Polished mild steel air headers offer enhanced durability, corrosion resistance, and a sleek finish, making them a cost-effective and reliable option for long-term industrial use.Q: When should I consider replacing or upgrading my air headers?

A: Replacement is recommended when you notice decreased efficiency, visible corrosion, or leaks. Upgrading may also be necessary to meet increased air distribution demands or comply with updated industry standards.Q: Where are your air headers manufactured and supplied from?

A: Our air headers are manufactured and supplied from our facilities in India, supported by our roles as manufacturer, exporter, distributor, supplier, and service provider nationwide.Q: What is the process for installing air headers in an existing system?

A: Installation involves securing the air header to the main line, connecting all necessary outlets, and ensuring airtight, leak-free joints for efficient air distribution. Professional guidance ensures optimal integration and performance.Q: How do air headers contribute to lowering power consumption?

A: By efficiently distributing compressed air to multiple outputs, our air headers minimize losses and reduce the need for excessive compression, leading to lower overall power usage in industrial operations.Q: What features make your air headers a cost-effective solution?

A: Our air headers combine sturdy mild steel construction, polished surfaces for longevity, low power consumption, and competitive pricing-delivering cost savings over their operational lifespan.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry