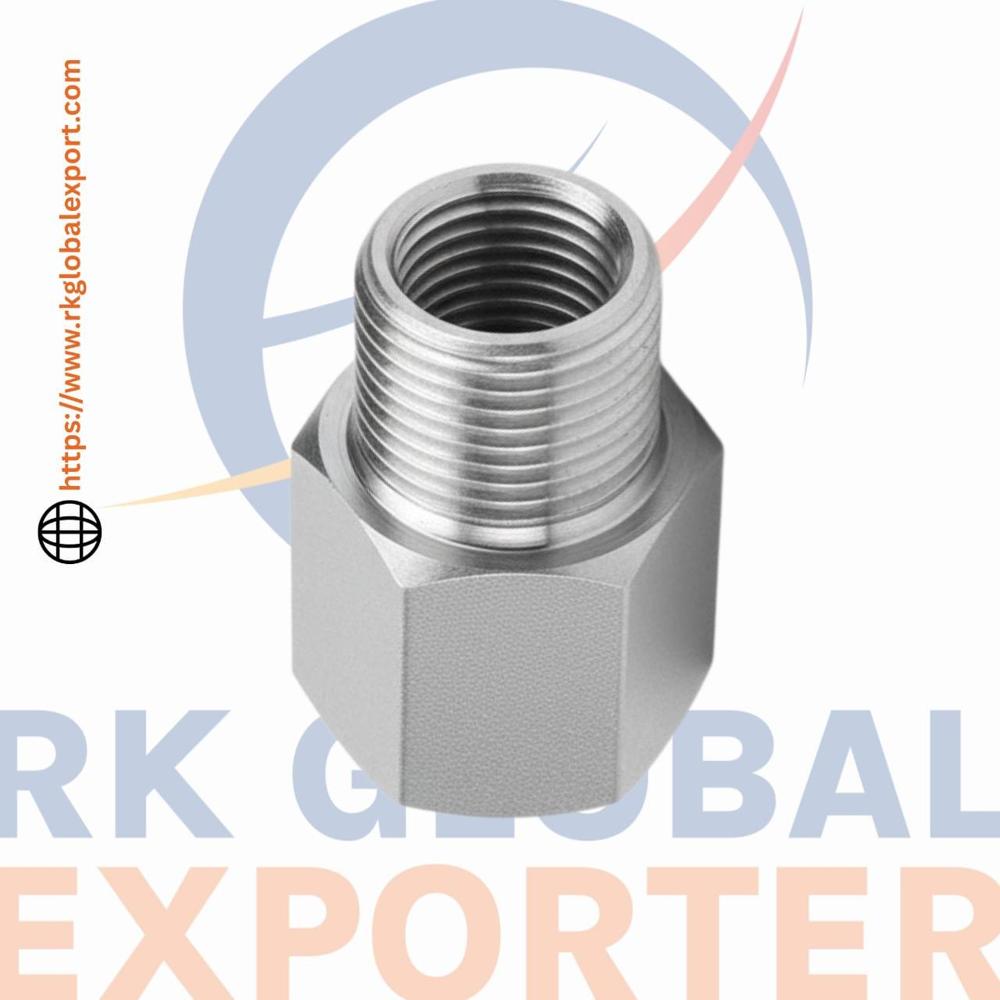

M16(M) X M20(F) SS304/SS316 Adaptor

Price 150.0 INR/ Piece

M16(M) X M20(F) SS304/SS316 Adaptor Specification

- Capacity

- Single Unit

- Dimension (L*W*H)

- Custom/Standard

- Diameter

- As per Standard Sizes

- Features

- Leak-proof, Durable

- Pressure Ratings

- High Pressure

- Working Pressure

- Up to 3000 psi

M16(M) X M20(F) SS304/SS316 Adaptor Trade Information

- Minimum Order Quantity

- 10 Pieces

- Delivery Time

- 7 Days

About M16(M) X M20(F) SS304/SS316 Adaptor

-

Product Name: M16 Male M20 Female Stainless Steel Adaptor

-

Size: M16 (Male) M20 (Female)

-

Thread Type: Metric Male to Metric Female

-

Material: Stainless Steel SS304 / SS316

-

Type: Threaded adaptor / reducer

-

Function: Connects different-size metric threaded components

-

Construction: Precision machined for secure, leak-tight fit

-

Pressure Rating: Suitable for standard industrial pressure applications

-

Corrosion Resistance: Excellent resistance to corrosion and chemicals

-

Temperature Range: Suitable for high and low temperature service

-

Applications: Instrumentation, control panels, hydraulic & pneumatic systems

-

Standards: Industrial-grade stainless steel fitting

-

-

Feature Description SS 304 / SS 316 Stainless Steel Construction Provides excellent strength, durability, and superior corrosion resistance. Metric Male Metric Female Thread Design Ensures secure, precise, and leak-proof connection between different metric thread sizes. High Corrosion & Chemical Resistance Suitable for water, oil, gas, steam, and chemical processing environments. Precision Machined Threads Guarantees accurate fitment, smooth assembly, and reliable sealing performance. Wide Industrial Usage Commonly used in instrumentation, industrial piping, control panels, and process systems.

Robust High-Pressure Performance

Designed to sustain up to 3000 psi working pressure, this adaptor ensures reliable performance in even the most demanding hydraulic and pneumatic environments. The use of premium SS304 or SS316 materials provides corrosion resistance and reinforces structural strength, making it an ideal choice for harsh and high-pressure applications.

Customizable Dimensions for Every Need

Our adaptors support both standard and tailor-made dimensions, allowing you to choose the perfect fit for your unique operation requirements. Whether your setup requires a specific length, width, or height, we offer solutions that integrate seamlessly into existing systems without compromising performance.

FAQ's of M16(M) X M20(F) SS304/SS316 Adaptor:

Q: How do I properly install the M16(M) X M20(F) SS304/SS316 Adaptor?

A: To install the adaptor, first ensure that the connecting threads are clean and free of debris. Align the male (M16) and female (M20) ends with corresponding components, then screw them together securely using the appropriate tools. Always check for tightness and confirm a leak-proof seal after installation.Q: What are the key benefits of using SS304 or SS316 material in this adaptor?

A: SS304 and SS316 stainless steels offer excellent corrosion resistance, durability, and high tensile strength, making the adaptor robust for high-pressure applications and suitable for harsh industrial environments.Q: Where can this adaptor be utilized effectively?

A: This adaptor is ideal for hydraulic, pneumatic, oil and gas, chemical, and manufacturing industries, where secure and leak-proof connections are crucial under high-pressure conditions.Q: When should I choose custom dimensions for this adaptor?

A: Opt for custom dimensions when standard sizes do not meet your specific installation requirements, ensuring optimal integration and performance in your system.Q: What is the process for sourcing the adaptor as a distributor or supplier in India?

A: Contact our sales team to discuss your specifications. We offer both standard and custom options, and support quantities as low as a single unit. Orders are processed efficiently for timely delivery both within India and for export.Q: How can I ensure the adaptor's durability over time?

A: Routine maintenance, such as inspecting for corrosion, verifying tightness, and ensuring proper installation, will extend the adaptor's operational lifespan, especially in high-pressure environments.Q: What makes this adaptor leak-proof and reliable for high-pressure use?

A: Precision engineering, high-quality SS304/SS316 materials, and adherence to strict manufacturing standards collectively result in a leak-proof, dependable adaptor designed for sustained high-pressure performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Instrumentation and Fittings Category

5 Way Manifold Valve

Price 3814.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Stainless Steel

Usage : Construction Industry

Port Size : 1/2inch

1 inch SS Tube Fitting

Price 110.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Stainless Steel

Usage : Structure Pipe

Port Size : 1 inch

Surface Finish : Polished

01_Ss 3 Way Manifold Valve

Price 2200.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Material : Stainless Steel

Usage : Construction Industry

Port Size : 2.5inch

Surface Finish : Polished

300 mm Cast Iron Ball Valve

Price 350.0 INR / Unit

Minimum Order Quantity : 50 Pieces

Material : Cast Iron

Usage : Industrial

Port Size : 300 mm

Surface Finish : Mirror

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry