Call: 08045815461

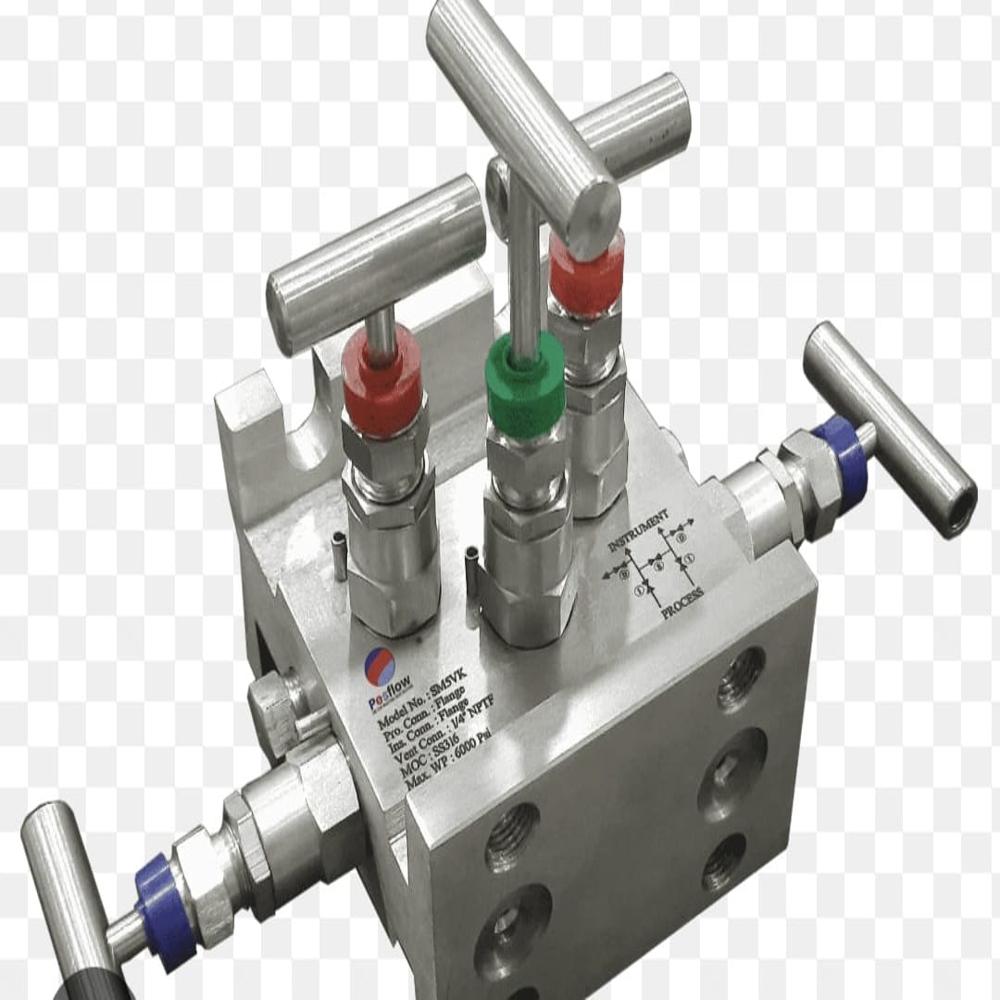

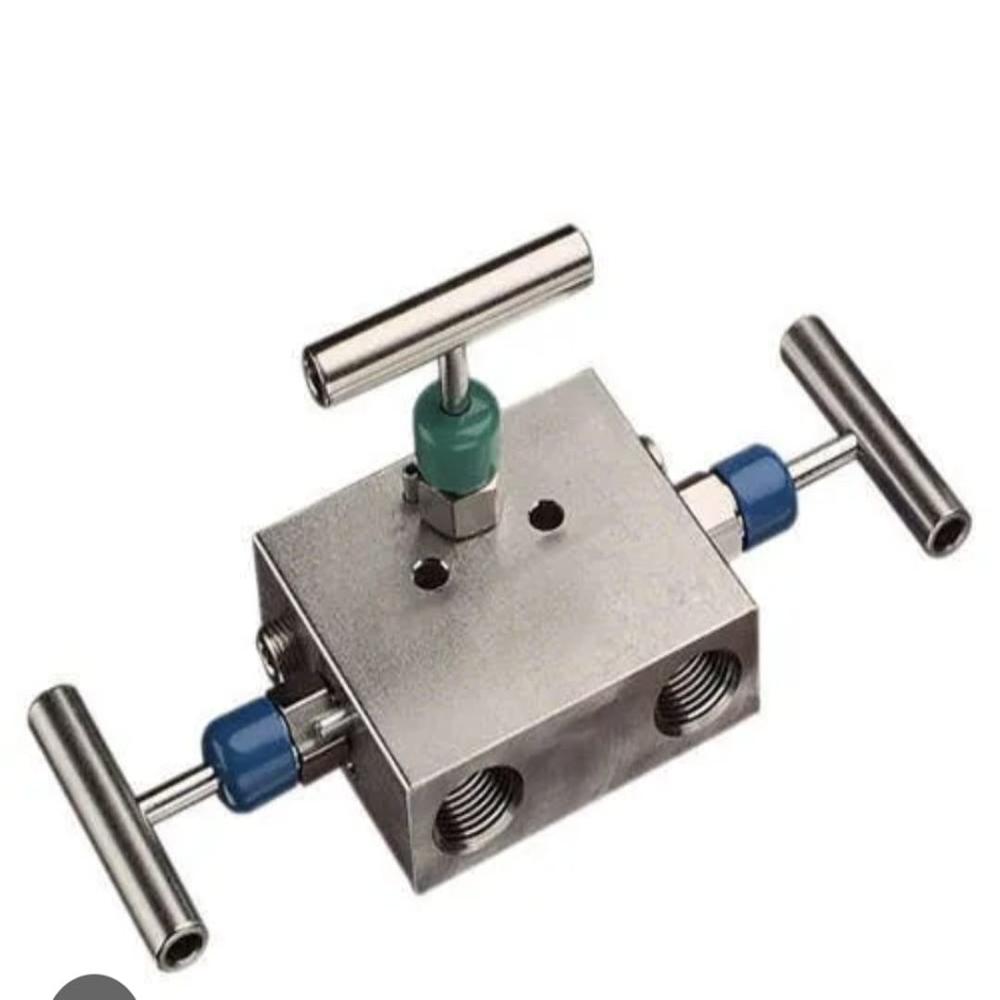

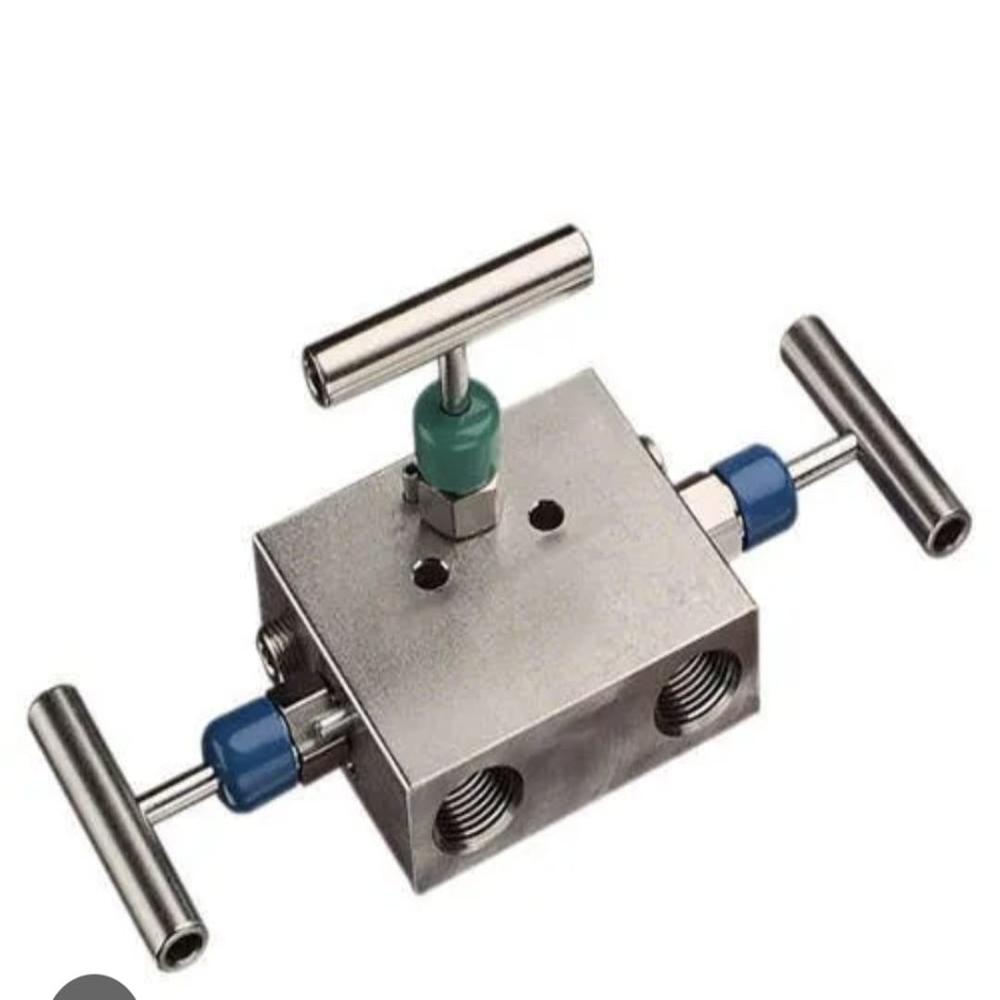

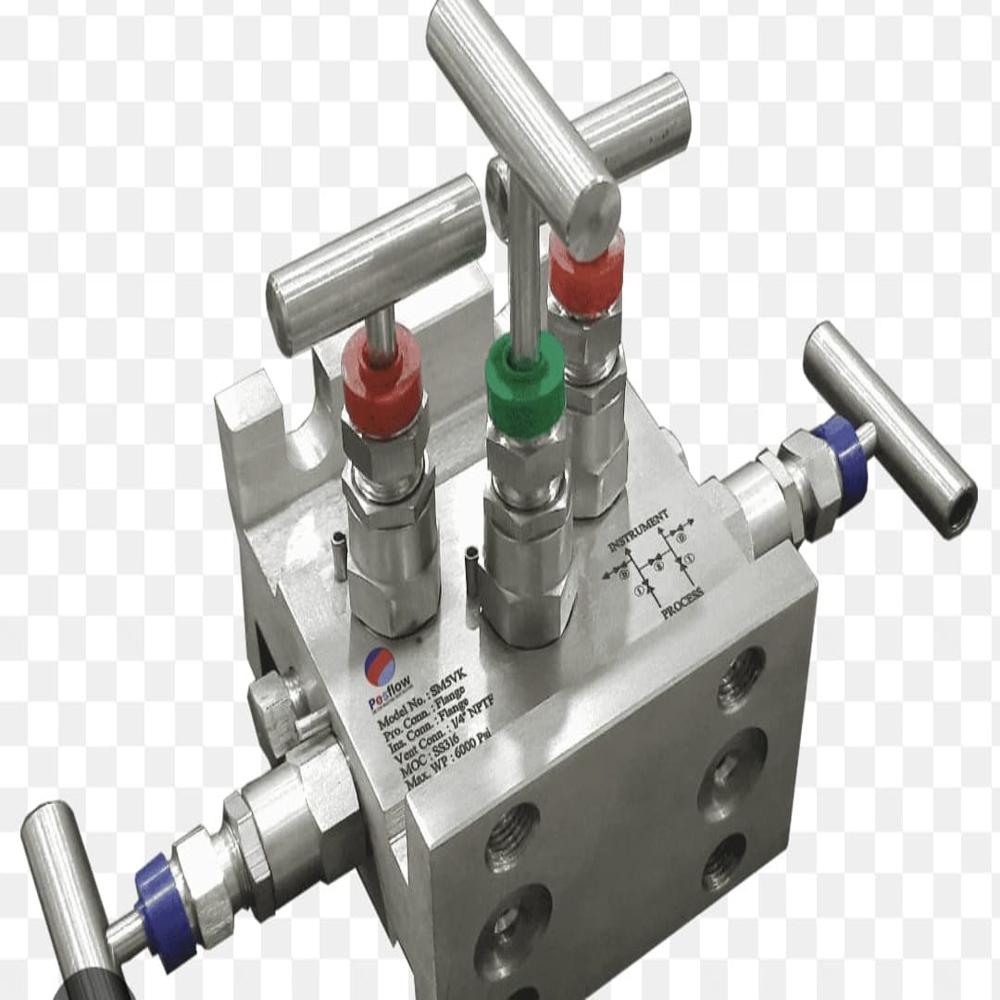

Manifolds Valves

Price 1000.0 INR/ Unit

Manifolds Valves Specification

- Usage

- Industrial

- Material

- Stainless Steel

- Size

- Standard

- Media

- Water

- Product Type

- Manifolds Valves

- Color

- Silver

- Width

- 300 mm Millimeter (mm)

- Surface

- Polishing

- Shape

- Round

- Application

- Water

Manifolds Valves Trade Information

- Minimum Order Quantity

- 10 Number

- Supply Ability

- 500 Per Month

- Delivery Time

- 7 Days

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

About Manifolds Valves

We have wide variety of Manifold Valves available as per the internation quality standards.

Range of Manifold.

- 2 Way ("H" Type ; "T" Type ; "R" Type)

- 3 Way ("H" Type ; "T" Type ; "R" Type)

- 5 way ("H" Type ; "T" Type ; "R" Type)

Material available in. Stainless Steel, CS, Duplex Stainless steel, etc.

Specification :

- Designed for connecting impulse lines & Transmitters

- Standard Connection : 1/2" Female NPT to 1/2" Female NPT

- Available in Pipe to Pipe, Pipe to Flange, Flange to Flange, Direct mount, Integral mount and Base Vent mounting options.

- Bonnet lock pin prevents accidental valve disassembly

- 100% pressure tested for shut-off and at all seals.

- 316 stainless steel construction for superior corrosion resistance

Durable Construction for Demanding Applications

Manufactured from high-grade stainless steel, our manifold valves deliver long-lasting performance, making them ideal for demanding industrial settings. The polished surface finish not only enhances resistance to corrosion but also provides a clean, professional appearance, ensuring the valves maintain their integrity during prolonged exposure to water.

Versatile Usage Across Industries

These valves are engineered with standard sizing and a round, 300 mm wide profile, allowing easy integration into existing water systems. Suitable for distributors, exporters, importers, manufacturers, suppliers, service providers, and traders, our manifold valves accommodate a range of industrial water management needs throughout India.

FAQ's of Manifolds Valves:

Q: How are these manifold valves typically used in industrial water management systems?

A: Our stainless steel manifold valves are primarily utilized to control, distribute, and regulate water flow in industrial water management systems. Their robust design ensures efficient operation even in high-demand environments.Q: What benefits do polished stainless steel manifold valves offer over other materials?

A: Polished stainless steel manifold valves provide enhanced corrosion resistance, increased durability, and a hygienic, easy-to-clean surface. This makes them more suitable than other materials for long-term use in water applications.Q: When should these manifold valves be installed within a water system?

A: These valves should be installed when precise control over water flow and distribution is required, such as during system upgrades, new installations, or maintenance activities in industrial settings.Q: Where can your manifold valves be sourced in India?

A: Our manifold valves are readily available across India through a network of distributors, exporters, importers, manufacturers, suppliers, service providers, and traders. This ensures easy access and reliable after-sales support.Q: What is the process for maintaining and cleaning these manifold valves?

A: Regular maintenance involves checking for leaks, ensuring fittings are secure, and cleaning the polished surface with appropriate non-corrosive cleaners. This helps maintain optimal performance and extends the valve's lifespan.Q: How does the round, 300 mm width design benefit water applications?

A: The round, 300 mm wide design allows for efficient water distribution and easy integration into standard industrial piping systems, supporting a consistent and controlled water flow in various applications.Q: What makes your manifold valves suitable for industrial export and supply?

A: Their standardized sizing, quality stainless steel construction, and polished finish make them compliant with international standards, ensuring suitability for export and reliable supply within different industrial sectors.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry