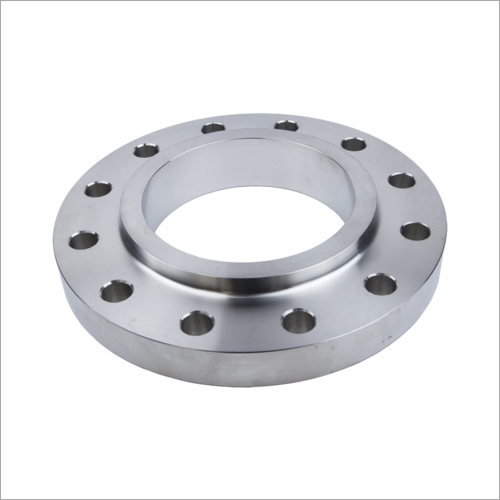

MS Screwed Flanges

Price 250.0 INR/ Piece

MS Screwed Flanges Specification

- Feature

- CNC Machine finishing and accuracy of drilling have been achieved by VMC/DRO. Crack free installation.

- Application

- Water, Air, Steam, Gas, Oil

- Product Type

- Other

- Material

- Steel

- Standard

- ASME

- Shape

- Round

- Size

- Customized

- Color

- Silver

MS Screwed Flanges Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About MS Screwed Flanges

Features:

- The high-quality antirust coating is provided.

- Crack-free installation.

- IBR Certified will also be provided upon request.

Application:

- WATER | AIR | STEAM | GAS | OIL

Precision Engineering for Optimal Performance

Every MS Screwed Flange undergoes advanced CNC machine finishing and VMC/DRO-driven drilling processes, delivering unmatched precision and consistency. This meticulous approach ensures dimensional accuracy and reliable sealing, minimizing installation errors and improving long-term pipeline integrity.

Versatility Across Applications

These flanges are designed to support various mediums like water, air, steam, gas, and oil. Their round shape and standard silver color allow seamless integration into a range of industrial systems, offering optimal solutions for diverse operational needs.

FAQ's of MS Screwed Flanges:

Q: How are MS Screwed Flanges manufactured for accuracy and durability?

A: MS Screwed Flanges are produced using state-of-the-art CNC machining and drilled precisely with VMC/DRO systems. This process ensures a smooth finish, exact dimensions, and high drilling accuracy, contributing to crack-free installation and extended component lifespan.Q: What industries commonly use MS Screwed Flanges?

A: These flanges are widely used in industries involving water, air, steam, gas, and oil transportation systems. Their robust construction and adherence to ASME standards make them suitable for industrial, commercial, and utility applications.Q: When is it advisable to use MS Screwed Flanges over other types?

A: MS Screwed Flanges are recommended when easy installation, maintenance, and replacement are required, especially in pipelines where quick assembly and disassembly are crucial. Their crack-resistant design makes them ideal for systems demanding regular servicing.Q: Where can I source MS Screwed Flanges in India?

A: You can purchase MS Screwed Flanges from authorized distributors, exporters, importers, manufacturers, suppliers, service providers, and traders throughout India, ensuring broad accessibility and reliable after-sales support.Q: What is the process for installing MS Screwed Flanges?

A: Installation involves aligning the flange to the pipe, screwing it securely, and ensuring the precise fit achieved through its CNC finish and VMC/DRO drilling. This approach guarantees a tight seal and crack-free, dependable connection.Q: What are the benefits of using ASME standard MS Screwed Flanges?

A: Utilizing flanges built to ASME standards provides assurance of quality, safety, and compatibility. The advanced manufacturing process further enhances durability, leak prevention, and installation efficiency, resulting in cost savings and operational reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Flanges Category

MS Weld Neck Flanges

Price 150.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Size : Customized

Product Type : Other, Weld Neck Flanges

Feature : CNC Machine finishing and accuracy of drilling have been achieved by VMC/DRO. Crack free installation.

Material : Steel

Threaded Screwed Flanges

Price 250.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Size : Customized

Product Type : Threaded Flanges

Feature : CNC Machine finishing and accuracy of drilling have been achieved by VMC/DRO. Crack free installation.

Material : Steel

MS Slip On Flanges

Price 250.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Size : Customized

Product Type : Slip On Flanges

Feature : CNC Machine finishing and accuracy of drilling have been achieved by VMC/DRO. Crack free installation.

Material : Steel

SS Weld Neck Flanges

Price 350.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Size : Customized

Product Type : Other

Feature : CNC Machine finishing and accuracy of drilling have been achieved by VMC/DRO. Crack free installation.

Material : Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry