Call: 08045815461

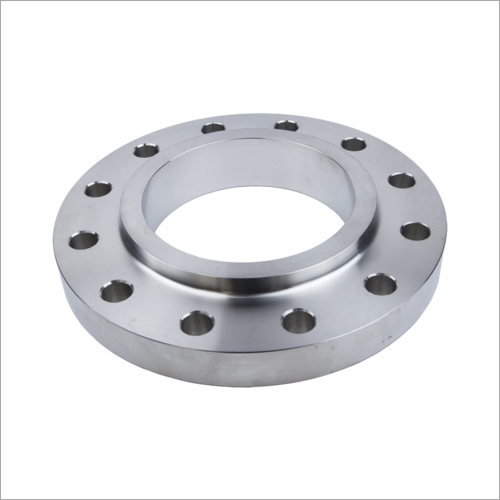

MS Weld Neck Flanges

Price 150.0 INR/ Piece

MOQ : 50 Pieces

MS Weld Neck Flanges Specification

- Feature

- CNC Machine finishing and accuracy of drilling have been achieved by VMC/DRO. Crack free installation.

- Application

- Water, Air, Gas, Steam, Oil

- Product Type

- Weld Neck Flanges

- Material

- Steel

- Standard

- ASME

- Shape

- Round

- Surface

- Galvanized

- Size

- Customized

- Color

- Silver

MS Weld Neck Flanges Trade Information

- Minimum Order Quantity

- 50 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About MS Weld Neck Flanges

Ever since our establishment, we are engaged in supplying excellent quality MS Weld Neck Flanges. These are designed as per ASME standards using high-quality anti-rust coated material. The flanges are designed specifically by CNC Machine finishing and accuracy of drilling has been achieved by VMC/DRO. Owing to its excellent dimensional stability, smooth surface finishing, and prolonged service life, this flange is highly appreciated and demanded by our clients. Moreover, to fulfill the varying requirements of our clients, we offer these MS Weld Neck Flanges in customized materials and sizes will be provided upon request

- Designed as per ASME standards.

- CNC Machine finishing and accuracy of drilling have been achieved by VMC/DRO

- High quality antirust coating is provided.

- Crack free installation.

- Customized material and size will be provided upon request

- IBR Certified will also be provided upon request.

Application:

WATER | AIR | STEAM | GAS | OIL

Specifications :

- N.Bore:A:B:C:D:F:J:L:P:T:Holes

- 15:89:11.1:1.6:35:30:21.3:48:60.3:15.9:4

- 20:98:12.7:1.6:43:38:26.7:52:69.8:15.9:4

- 25:108:14.3:1.6:51:49:33.4:56:79.4:15.9:4

- 32:117:15.9:1.6:64:59:42.2:57:88.9:15.9:4

- 40:127:17.5:1.6:73:65:48.3:62:98.4:15.9:4

- 50:152:19:1.6:92:78:60.3:64:120.6:19:4

- 65:178:22.2:1.6:105:90:73:70:139.7:19:4

- 80:190:23.8:1.6:127:108:88.9:70:152.4:19:4

- 90:216:23.8:1.6:140:122:101.6:71:177.8:19:8

- 100:229:23.8:1.6:157:135:114.3:76:190.5:19:8

- 125:254:23.8:1.6:186:164:141.3:89:215.9:22.2:8

- 150:279:25.4:1.6:216:192:168.3:89:241.3:22.2:8

- 200:343:28:1.6:270:246:219.1:102:288.4:22.2:8

- 250:406:30.2:1.6:324:305:273:102:362:25.4:12

- 300:483:34.8:1.6:381:365:323.9:114:431.8:25.4:12

-

- N.Bore:A:B:C:D:F:J:L:P:T:Holes

- 15:95:14.3:1.6:35:38:21.3:52:66.7:15.9:4

- 20:117:15.9:1.6:43:48:26.7:57:82.6:19:4

- 25:124:17.5:1.6:51:54:33.4:62:88.9:19:4

- 32:133:19:1.6:64:64:42.2:65:98.4:19:4

- 40:156:20.6:1.6:73:70:48.3:68:114.3:22.2:4

- 50:165:22.2:1.6:92:84:60.3:70:127:19:8

- 65:190:25.4:1.6:105:100:73:76:149.2:22.2:8

- 80:210:28.6:1.6:127:117:88.9:79:168.3:22.2:8

- 90:229:30.2:1.6:140:133:101.6:81:184.2:22.2:8

- 100:254:31.8:1.6:157:146:114.3:86:200.2:22.2:8

- 125:279:34.9:1.6:186:178:141.3:98:235:22.2:8

- 150:318:36.8:1.6:216:206:168.3:98:269.9:22.2:12

- 200:381:41.3:1.6:270:260:219.1:111:330.2:25.4:12

- 250:444:47.6:1.6:324:321:273:117:387.4:28.6:16

- 300:521:50.8:1.6:381:375:323.9:130:450.8:31.8:16

Precision Engineering for Optimal Performance

MS Weld Neck Flanges are crafted using advanced CNC machines and VMC/DRO technology. This guarantees high drilling accuracy, tight tolerances, and a flawless finish. The resulting product ensures leak-free connections, excellent mechanical strength, and consistent performance in demanding environments.

Superior Durability and Protection

Each flange is fabricated from quality steel and treated with a galvanized surface. This finish provides exceptional corrosion resistance, enhancing the lifespan of the product even in aggressive media such as steam, oil, or water. Our flanges maintain their integrity, offering long-term reliability for critical applications.

Customized Solutions for Diverse Industries

We offer MS Weld Neck Flanges in a variety of sizes tailored to individual client specifications. Our comprehensive services span distribution, manufacturing, supplying, and exporting to support distinct requirements across water supply, gas transmission, industrial steam lines, and petroleum sectors throughout India.

FAQ's of MS Weld Neck Flanges:

Q: How are MS Weld Neck Flanges manufactured for crack-free installation?

A: MS Weld Neck Flanges are produced using high-precision CNC machines and drilling equipment like VMC/DRO. This meticulous process achieves superior accuracy in drilling and finishing, ensuring a perfect fit and crack-free installation during application.Q: What standards do your MS Weld Neck Flanges adhere to?

A: Our flanges are manufactured in compliance with ASME standards, ensuring that they meet rigorous industry requirements for safety, compatibility, and performance in water, air, gas, steam, and oil systems.Q: When should I choose a galvanized MS Weld Neck Flange?

A: A galvanized MS Weld Neck Flange is ideal for environments where enhanced corrosion resistance is required, such as those exposed to water, steam, or chemicals. The galvanized surface protects the steel from oxidation, prolonging the flange's operational lifespan.Q: Where can these flanges be deployed effectively?

A: These flanges are suitable for use in pipelines and systems transporting water, air, gas, steam, and oil. Industries such as water supply, oil and gas, and power generation throughout India benefit from their robust performance and versatility.Q: What is the usual process involved in customizing the size of the MS Weld Neck Flanges?

A: Clients provide their specific dimensional requirements, and our team engineers the flanges using advanced manufacturing tools to deliver precise, tailored solutions that meet each application's unique needs.Q: How do MS Weld Neck Flanges improve operational efficiency?

A: By offering highly accurate drilling and a galvanized, durable surface, these flanges ensure secure, leak-free connections that minimize maintenance, reduce downtime, and enhance the reliability of pipeline systems.Q: What are the benefits of sourcing MS Weld Neck Flanges from your company in India?

A: As a trusted distributor, exporter, importer, manufacturer, service provider, supplier, and trader, we guarantee superior product quality, complete after-sales support, and tailored logistical solutions for clients across the country.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Flanges Category

Threaded Screwed Flanges

Price 250.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : Threaded Flanges

Size : Customized

Shape : Round

Standard : ASME

Industrial Welding Neck Flanges

Price 250.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : Pipe Flanges

Size : Customized

Shape : Round

Standard : ASME

Lap Joint Flanges

Price 100.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : Other

Size : Customized

Shape : Round

Standard : ASME

MS Slip On Flanges

Price 250.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : Slip On Flanges

Size : Customized

Shape : Round

Standard : ASME

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry