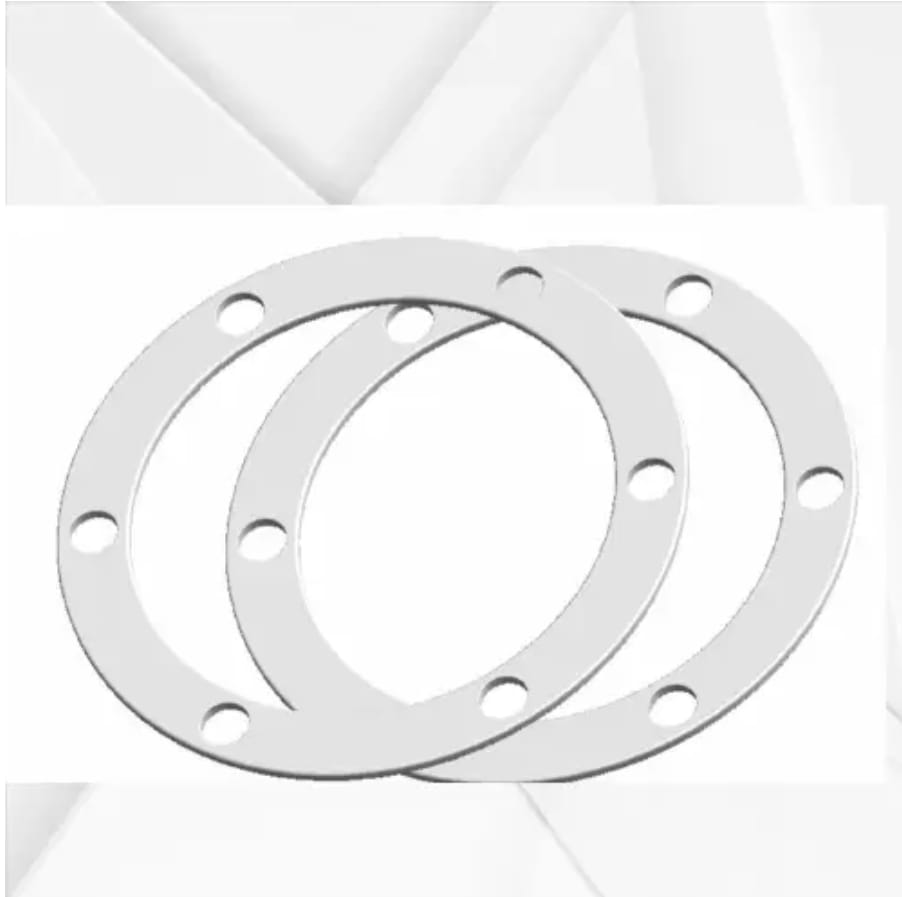

PTFE Gasket

Price 50.0 INR/ Piece

PTFE Gasket Specification

- Medium

- Oil, Air, Gas, Water

- Material

- Other

- Shape

- Ring Gasket

- Product Type

- Gasket

- Color

- Black

- Application

- Industrial

PTFE Gasket Trade Information

- Minimum Order Quantity

- 50 Pieces, Piece

- Supply Ability

- 10000 Pieces, Piece Per Month

- Delivery Time

- 7 Days

About PTFE Gasket

- It is made from PTFE sheets, molded rods, tubes and other materials.

- PTFE has best chemical resistance, low friction coefficient, high aging stability, insulation (electrical) & wear resistance.

- It can work from -180 Deg C to 260 Deg C

- Best gasket for sealing application is PTFE. It can be manufacture in different sizes and shapes.

- Cut Gasket & articles.

- Expanded PTFE Cut gaskets/sheets

- Diaphragm gaskets

- Encapsulated O ring

- Sleeve

- Bush

- Thread Seal tape

Versatile Applications Across Industries

PTFE Ring Gaskets are ideally suited for critical applications in oil, air, gas, and water systems. Their outstanding chemical resistance and sealing capabilities make them indispensable for various industrial sectors. Whether dealing with aggressive fluids or extreme temperatures, these gaskets maintain excellent performance over extended service periods.

Reliable Supply and Professional Service

As a leading supplier, distributor, and manufacturer in India, we ensure timely availability and technical support for PTFE Ring Gaskets. Our broad presence as exporter, importer, and trader underlines our ability to meet both domestic and international demands, supporting customers with prompt service and expertise.

FAQ's of PTFE Gasket:

Q: How are PTFE Ring Gaskets used in industrial systems?

A: PTFE Ring Gaskets are installed between two joining surfaces, such as pipe flanges, to create a leak-proof seal. Their use in oil, air, gas, and water systems helps prevent fluid leaks and enhances safety and efficiency in industrial applications.Q: What benefits does black PTFE offer as a gasket material?

A: Black PTFE provides superior chemical resistance, low friction, and excellent sealing properties. Its non-stick surface and stability under high temperatures make it suitable for demanding industrial environments, contributing to longer service life and reduced maintenance.Q: When should PTFE Ring Gaskets be replaced in industrial applications?

A: PTFE Ring Gaskets should be inspected regularly during maintenance cycles and replaced if they show signs of wear, deformation, or leakage. Scheduling replacements proactively, especially in high-pressure or critical systems, minimizes downtime and ensures reliable operation.Q: Where can I source PTFE Ring Gaskets in India?

A: You can source PTFE Ring Gaskets from reputable distributors, exporters, importers, manufacturers, service providers, suppliers, and traders located across India. We offer comprehensive support and timely delivery for both domestic and global clients.Q: What is the manufacturing process for PTFE Ring Gaskets?

A: PTFE Ring Gaskets are manufactured by molding or cutting high-quality PTFE sheets into precise ring shapes. Advanced fabrication techniques ensure accurate dimensions and reliable sealing performance, tailored to various industrial standards and applications.Q: How do PTFE Ring Gaskets improve industrial system reliability?

A: By providing a resilient and chemically inert seal, PTFE Ring Gaskets minimize the risk of leaks and equipment failure. This enhances system reliability, extends equipment lifespan, and safeguards workers and the environment in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Gaskets & Sealing Product Category

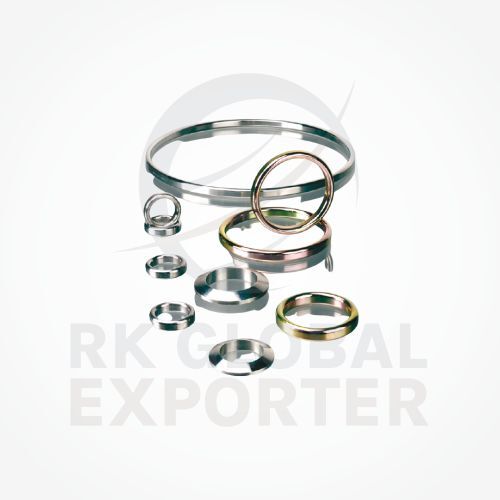

RTG Ring (Octagonal Ring Gasket)

Price 150.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : Ring Gasket

Application : Industrial

Color : Silver,Golden

Size : As per ASME class150, 300 & 600 table

Sealing Packing

Price 25.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : Ring Gasket

Application : Industrial

Color : White

Size : As per ASME class150, 300 & 600 table

Non Asbestos Gasket

Price 25.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : Ring Gasket

Application : Industrial

Color : Multicolor

Size : As per ASME class150, 300 & 600 table

Spiral Wound Gasket

Price 50.0 INR / Piece

Minimum Order Quantity : 50 Pieces, Piece

Shape : Ring Gasket

Application : Industrial

Color : Green

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry