Call: 08045815461

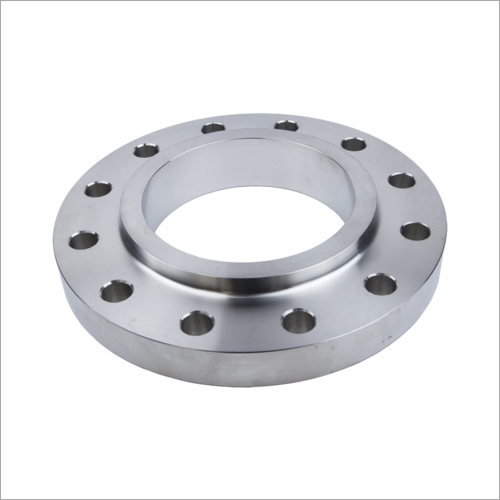

Stainless Steel Screwed Flanges

Price 350.0 INR/ Piece

MOQ : 50 Pieces

Stainless Steel Screwed Flanges Specification

- Application

- Water, Steam, Gas, Oil, Air

- Feature

- CNC Machine finishing and accuracy of drilling have been achieved by VMC/DRO. Crack free installation.

- Product Type

- Other

- Material

- Steel

- Standard

- ASME

- Shape

- Round

- Size

- Customized

- Color

- Silver

Stainless Steel Screwed Flanges Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Stainless Steel Screwed Flanges

Betting on the individual demands of the customers, we as a prime supplier offer an extensive variety of Stainless Steel Screwed Flanges that are treasured for smooth completion and excellent quality. They are utilized for collecting and dismantling purposes and are offered in standard grades. These flanges are very much requested for features, such as perfectly complete, superlative execution, best grade materials, etc. Stainless Steel Screwed Flanges are quality tried and comes in budgetary breaking points.

- Designed as per ASME standards.

- CNC Machine finishing and accuracy of drilling have been achieved by VMC/DRO

- High quality antirust coating is provided.

- Crack free installation.

- Customized material and size will be provided upon request

- IBR Certified will also be provided upon request.

Application:

WATER | AIR | STEAM | GAS | OIL

Specifications :

- N.Bore:A:B:C:D:E:F:K:M:P:T:Holes

- 15:89:11.1:1.6:35:16:30:-:16:60.3:15.9:4

- 20:98:12.7:1.6:43:16:38:-:16:69.8:15.9:4

- 25:108:14.3:1.6:51:17:49:-:17:79.4:15.9:4

- 32:117:15.9:1.6:64:21:59:-:21:88.9:15.9:4

- 40:127:17.5:1.6:73:22:65:-:22:98.4:15.9:4

- 50:152:19:1.6:92:25:78:-:25:120.6:19:4

- 65:178:22.2:1.6:105:29:90:-:29:139.7:19:4

- 80:190:23.8:1.6:127:30:108:-:30:152.4:19:4

- 90:216:23.8:1.6:140:32:122:-:32:177.8:19:8

- 100:229:23.8:1.6:157:33:135:-:33:190.5:19:8

- 125:254:23.8:1.6:186:37:164:-:37:215.9:22.2:8

- 150:279:25.4:1.6:216:40:192:-:40:241.3:22.2:8

- 200:343:28:1.6:270:44:246:-:44:288.4:22.2:8

- 250:406:30.2:1.6:324:49:305:-:49:362:25.4:12

- 300:483:34.8:1.6:381:56:365:-:56:431.8:25.4:12

- N. Bore:A:B:C:D:E:F:K:M:P:T:Holes

- 15:95:14.3:1.6:35:22:38:23.5:16:66.7:15.9:4

- 20:117:15.9:1.6:43:25:48:29:16:82.6:19:4

- 25:124:17.5:1.6:51:27:54:36:17:88.9:19:4

- 32:133:19:1.6:64:27:64:44.5:21:98.4:19:4

- 40:156:20.6:1.6:73:30:70:50.5:22:114.3:22.2:4

- 50:165:22.2:1.6:92:33:84:63.5:29:127:19:8

- 65:190:25.4:1.6:105:38:100:76:32:149.2:22.2:8

- 80:210:28.6:1.6:127:43:117:92:32:168.3:22.2:8

- 90:229:30.2:1.6:140:44:133:105:37:184.2:22.2:8

- 100:254:31.8:1.6:157:48:146:118:37:200.2:22.2:8

- 125:279:34.9:1.6:186:51:178:145:43:235:22.2:8

- 150:318:36.8:1.6:216:52:206:171:46:269.9:22.2:12

- 200:381:41.3:1.6:270:62:260:222:51:330.2:25.4:12

- 250:444:47.6:1.6:324:67:321:276:56:387.4:28.6:16

- 300:521:50.8:1.6:381:73:375:329:60:450.8:31.8:16

Engineered for Versatility and Precision

Our stainless steel screwed flanges are manufactured using advanced CNC machining and VMC/DRO technology. This ensures each flange meets the highest standards for drilling accuracy and finishing, delivering reliable, crack-free installations across a range of applications like water, steam, gas, oil, and compressed air systems.

Custom Solutions for Every Project

Offering complete customization, these round ASME-standard flanges are available in any size to meet the specific needs of our clients. Their robust construction and silver finish make them suitable for varied industries, providing flexibility and performance in even the most challenging installations.

FAQ's of Stainless Steel Screwed Flanges:

Q: How are stainless steel screwed flanges installed to ensure a crack-free joint?

A: Installation is simplified by the precision machining and accuracy of the drilled holes, achieved through VMC/DRO technology. This meticulous process allows for tight fitting and secure connections, significantly reducing the risk of cracking during or after setup.Q: What applications are best suited for these flanges?

A: These flanges are ideal for systems carrying water, steam, gas, oil, and air. Their robust construction and leak-resistant design make them suitable for industrial, commercial, and utility piping projects.Q: When should one opt for customized size flanges?

A: Custom sizing is recommended when standard dimensions do not meet specific project needs or to ensure compatibility with existing pipework. Our facility can tailor flanges to precise measurements for seamless integration.Q: Where does your company distribute and supply these flanges?

A: We operate across India, serving as distributors, exporters, importers, manufacturers, suppliers, traders, and service providers, offering broad access to quality stainless steel screwed flanges for diverse industries.Q: What is the manufacturing process of these flanges?

A: Production involves selecting high-grade steel, precision CNC machining for superior finish, and VMC/DRO drilling for exact hole placement. This process ensures each flange meets ASME standards and is ready for durable, high-performance use.Q: How does CNC finishing benefit the end-user?

A: CNC machining ensures uniformity and accuracy, translating to easier installation, enhanced sealing, and reduced risk of leaks or structural issues over the lifespan of the piping system.Q: Can these flanges be used in high-pressure systems?

A: Yes, their crack-free installation, accurate drilling, and robust design make these flanges suitable for high-pressure environments commonly found in industrial water, steam, gas, oil, and air systems.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Flanges Category

Threaded Screwed Flanges

Price 250.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : Round

Material : Steel

Standard : ASME

Size : Customized

MS Weld Neck Flanges

Price 150.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : Round

Material : Steel

Standard : ASME

Size : Customized

MS Slip On Flanges

Price 250.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : Round

Material : Steel

Standard : ASME

Size : Customized

Slip On Flanges

Price 100.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : Round

Material : Steel

Standard : ASME

Size : Customized

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry