Call: 08045815461

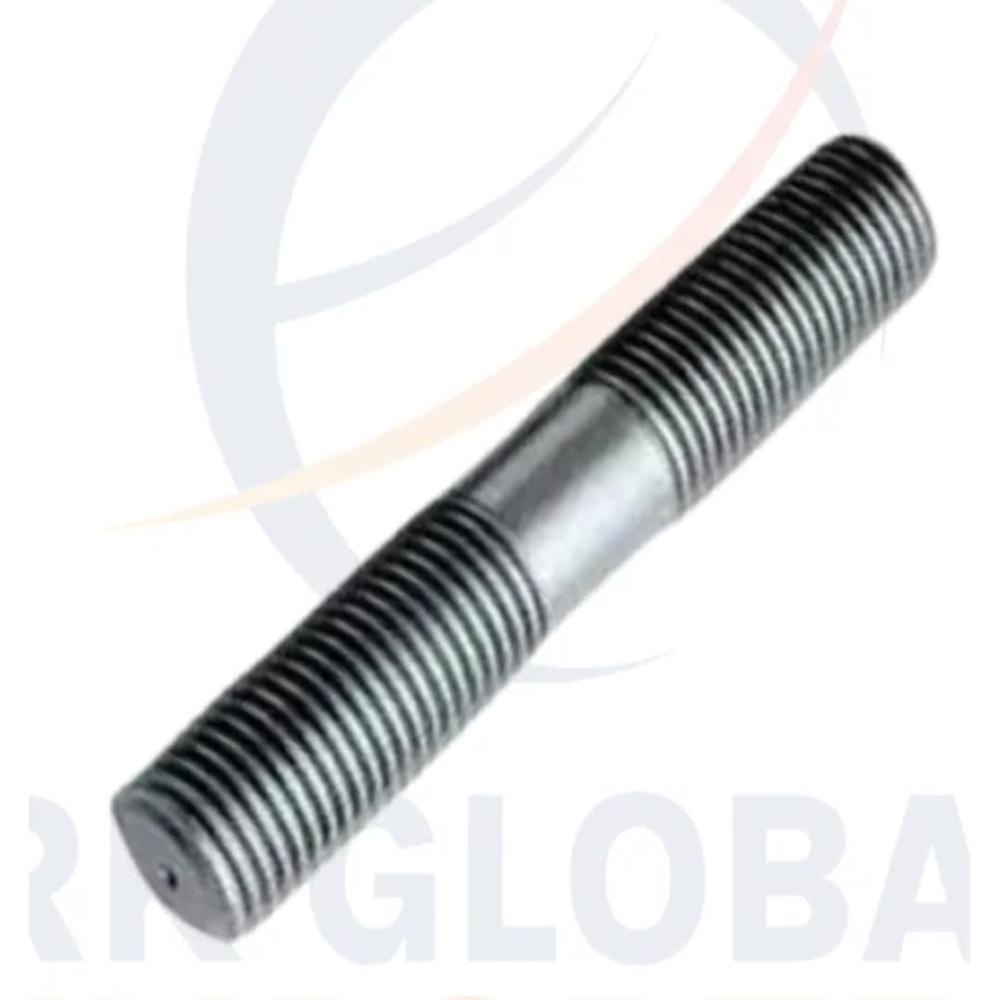

Stud Bolt

Price 110.0 INR/ Piece

MOQ : 50 Pieces, Piece

Stud Bolt Specification

- Shape

- Hexagonal

- Feature

- - Excellent quality - Non corrosive - Fine finishing

- Finish

- Electroplated

- Usage

- Pipe clamps are recommended for suspension for cold pipe lines that may or may not be insulated. Pipe Clamps are usually used on pipes to grasp it and facilitate hoisting or suspension.

- Material

- Steel

- Application

- Construction

- Color

- Silver

Stud Bolt Trade Information

- Minimum Order Quantity

- 50 Pieces, Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces, Piece Per Day

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

About Stud Bolt

- Stud Bolts are are fully threaded headless bolts used on Pipeline flanges for joining the pipelines.

- The main advantage of Stud Bolts over the Hex Bolts is that, it can be tightened from both the ends by holding one end with nut.

- The other type of Stud Bolt is the Engineering Stud which is also known as both end threaded bolt with unthreaded portion in the center.

- Type:Full threads, Partial Threads, and customized as per requirements.

- Size :Nom Dia: 1/4 inch to 4inch 6-100 mm Tailor made if required.

- Length: As Per Standard or Up to any Length

- Specification / Standard:ASTM / ASME / BS / DIN / BS EN ISO

- Material:C.S., M.S., Alloy Steel, Ferritic and Austenitic Stainless Steel

- Threads:UNC, 8UN, UNF, Metric Coarse and Fine Series.

- Surface Finish: Self Color, Hot Dip Galvanized, Electro Galvanized, Di Chromate P.T.F.E. Coated or any other as per order requirement

Feature Description High-Quality Mild Steel Manufactured from premium MS for strength and durability in industrial use. Accurate Threading Precision-machined threads ensure secure and vibration-resistant fastening. Corrosion Protection Available with zinc-plated or galvanized coating for extended lifespan. Tensile Strength Designed to withstand high stress and mechanical loads effectively. Applications Commonly used in construction, machinery, flange joints, and automotive assemblies.

Exceptional Durability and Quality

Manufactured from robust steel, these stud bolts are built to endure harsh environments and heavy loads without compromising structural integrity. Their excellent quality guarantees reliability in crucial construction tasks, making them the preferred choice for pipe suspension systems and facility installations.

Corrosion-Resistant Electroplated Finish

Boasting a high-quality electroplated silver coating, our stud bolts exhibit remarkable resistance to corrosion, ensuring longevity even in moist or chemically exposed conditions. This finish also contributes to their fine, aesthetically pleasing appearance, expanding their versatility in various construction and engineering applications.

FAQ's of Stud Bolt:

Q: How are stud bolts used for pipe clamp suspension in construction?

A: Stud bolts are fitted into pipe clamps, which then grasp the pipelines securely. This setup is recommended for suspending cold pipelines, including those with or without insulation, ensuring stable hoisting and effective support in construction projects.Q: What is the benefit of the electroplated silver finish on these stud bolts?

A: The electroplated silver finish provides outstanding resistance to corrosion, extending the lifecycle of the bolts in environments exposed to moisture or chemicals. It also enhances the visual appeal and ensures a smooth, fine surface.Q: When should I choose non-corrosive stud bolts for my project?

A: Non-corrosive stud bolts are best selected when working in environments where moisture and other corrosive elements are present, such as outdoor or industrial applications, to maintain secure and reliable connections over time.Q: Where are these hexagonal stud bolts most commonly utilized?

A: These stud bolts are widely applied in construction sites, particularly for supporting cold pipelines during suspension and hoisting. Their use is prevalent across industrial and commercial facilities throughout India.Q: What is the process for using pipe clamps and stud bolts together?

A: The process involves positioning the pipe clamp around the pipeline, installing the stud bolt through the clamp's openings, and securing both ends. This creates a firm hold, enabling safe suspension or hoisting of the pipeline.Q: Who can benefit from using these stud bolts supplied by your company?

A: Distributors, exporters, importers, manufacturers, service providers, suppliers, and traders involved in construction or industrial pipeline projects in India can all benefit from our reliable stud bolts due to their quality and versatility.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Fasteners Category

Eye Bolt

Price 25.0 INR / Piece

Minimum Order Quantity : 50 Pieces, Piece

Material : Steel

Shape : Hexagonal

Feature : Excellent quality Non corrosive Fine finishing

Finish : Electroplated

Anchor Bolt

Price 2500.0 INR / Piece

Minimum Order Quantity : 50 Pieces, Piece

Material : Steel

Shape : Hexagonal

Feature : Excellent quality Non corrosive Fine finishing

Finish : Electroplated

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry