Rubber Gasket

Price 25.0 INR/ Piece

Rubber Gasket Specification

- Medium

- Oil, Water, Air, Gas

- Material

- Rubber

- Shape

- Ring Gasket

- Product Type

- Gasket

- Size

- Customized

- Application

- Industrial

Rubber Gasket Trade Information

- Minimum Order Quantity

- 50 Pieces, Piece

- Supply Ability

- 10000 Pieces, Piece Per Month

- Delivery Time

- 7 Days

About Rubber Gasket

- Silicone Gasket.

- Neoprene Gasket

- EPDM gasket

- Silicone Sponge Gasket

- Viton Gasket

- Natural Rubber Gasket

- SBR gasket

- Nitrile Gasket

- It Produce abrasion resistance.

- They are suitable for application with alkalis and acid chemicals

- The properties of type of rubbers are different so it varies with varying the sheet of rubber

Product Specification.

- Sr. No.:Product:Thickness:Sheet Size

- 1:Buna-N/Nitrile Rubber Gasket:0.5 mm to 50 mm:1.4 meter to (20 x X) meter

- 2:EPDM Rubber Gasket:0.5 mm to 50 mm:1.4 meter to (20 x X) meter

- 3:Neoprene Rubber:0.5 mm to 50 mm:1.4 meter to (20 x X) meter

- 4:Silicone Rubber:0.5 mm to 50 mm:1.4 meter to (20 x X) meter

- 5:Viton Rubber:0.5 mm to 50 mm:1.4 meter to (20 x X) meter

Application:

- Can be used in pipelines

- Can be used in Mining

- Can be used in mechanisms like plumbing

- Can be used in Aeronautics

- Can be used in Pharmaceutical Sector, etc.

Engineered for Demanding Industrial Applications

Designed to meet the rigors of oil, water, air, and gas handling systems, our rubber ring gaskets provide robust sealing performance and longevity. We supply these gaskets in custom dimensions, ensuring a perfect fit for your application across industries such as manufacturing, petrochemical, and utilities.

Trusted Partner in India for Rubber Gaskets

As a manufacturer, supplier, distributor, exporter, importer, service provider, and trader based in India, we ensure consistent quality, prompt delivery, and dedicated technical support. Whether you require standard or bespoken gasket solutions, our team delivers excellence at every stage of the process.

FAQ's of Rubber Gasket:

Q: How do I select the right rubber ring gasket for my industrial application?

A: Selecting the proper rubber ring gasket involves assessing the application's operating conditions, including temperature, pressure, and the medium-such as oil, water, air, or gas. Providing us with your specifications allows us to customize the gasket for an optimal fit.Q: What materials are used in your rubber gaskets, and why are they suitable for industrial use?

A: We use high-grade rubber compounds specifically chosen for compatibility with various industrial media. The rubber provides excellent flexibility, chemical resistance, and sealing capability, making it ideal for demanding environments.Q: When is it recommended to replace a rubber ring gasket in oil or gas systems?

A: Gaskets should be inspected regularly and replaced if there are signs of wear, cracking, or loss of elasticity. Replacement intervals depend on operational stress and media exposure, but periodic preventive maintenance is advised for safety and efficiency.Q: Where are your rubber ring gaskets typically used within industrial settings?

A: Our rubber gaskets are widely used in pipelines, flanges, pumps, and valve assemblies in industries such as oil and gas, water treatment, and manufacturing, wherever reliable sealing for fluids or gases is essential.Q: What is the process for ordering customized rubber gaskets from your company in India?

A: You can contact us with your detailed requirements, including application details and size specifications. Our team will guide you through the customization process, provide a quote, and ensure timely production and delivery.Q: How should rubber gaskets be used and installed for best performance?

A: Ensure the mating surfaces are clean and free from debris before installation. Proper alignment and compression are essential for an effective seal. Follow torque specifications and avoid over-tightening, which may damage the gasket.Q: What are the primary benefits of using your rubber ring gaskets in industrial systems?

A: Our rubber ring gaskets provide excellent sealing performance, resist a variety of fluids and gases, and offer long service life. Customization options and quality manufacturing make them a reliable and cost-effective solution for diverse industrial needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Gaskets & Sealing Product Category

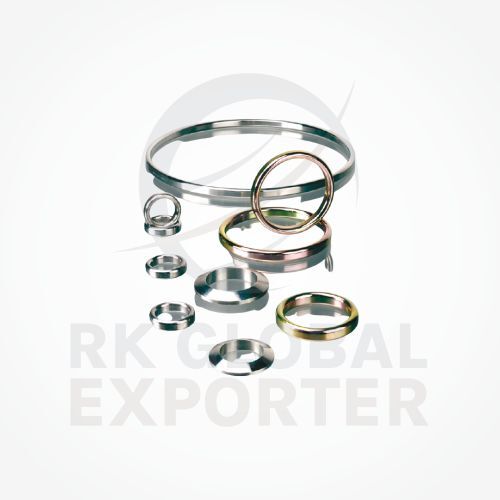

RTG Ring (Octagonal Ring Gasket)

Price 150.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : Ring Gasket

Application : Industrial

Medium : Oil, Gas, Water, Air

Product Type : RTG Ring (Octagonal Ring Gasket)

Non Asbestos Gasket

Price 25.0 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : Ring Gasket

Application : Industrial

Product Type : Non Asbestos Gasket

PTFE Gasket

Price 50.0 INR / Piece

Minimum Order Quantity : 50 Pieces, Piece

Shape : Ring Gasket

Application : Industrial

Medium : Oil, Air, Gas, Water

Product Type : Gasket

Spiral Wound Gasket

Price 50.0 INR / Piece

Minimum Order Quantity : 50 Pieces, Piece

Shape : Ring Gasket

Application : Industrial

Medium : Water, Air, Gas, Oil

Product Type : Spiral Wound GasketÂ

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry